Your Professional Slitting Machine Manufacturer

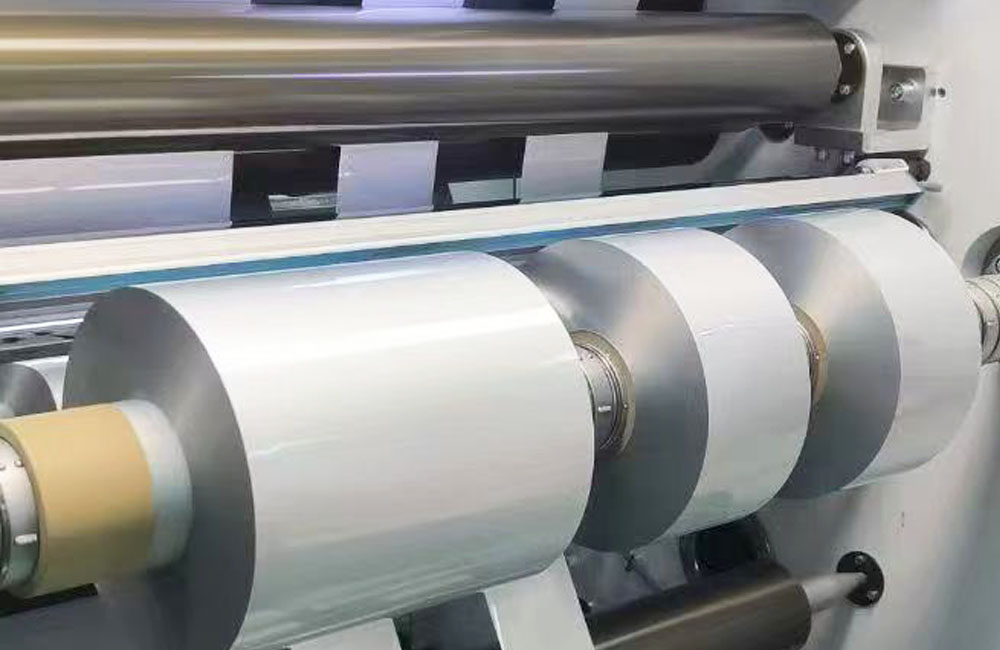

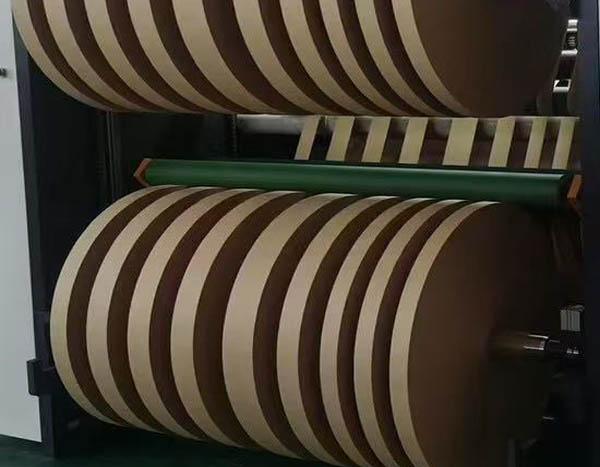

ZONBON is professional slitting machine supplier,our slitting machine can slit different kind of materials such film,paper,non woven,metalized film,laminating film

ZONBON have been more than 18years experience in slitting machine field.Our slitting machine adopt latest technology,it can slit large roll with small roll with narrow width for different slitting material,such as paper,film.

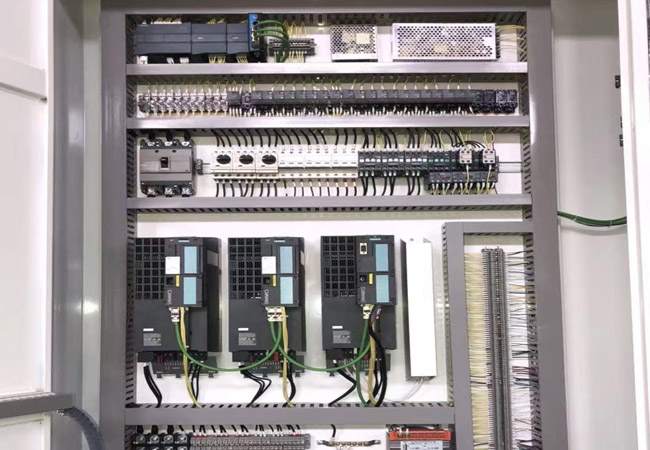

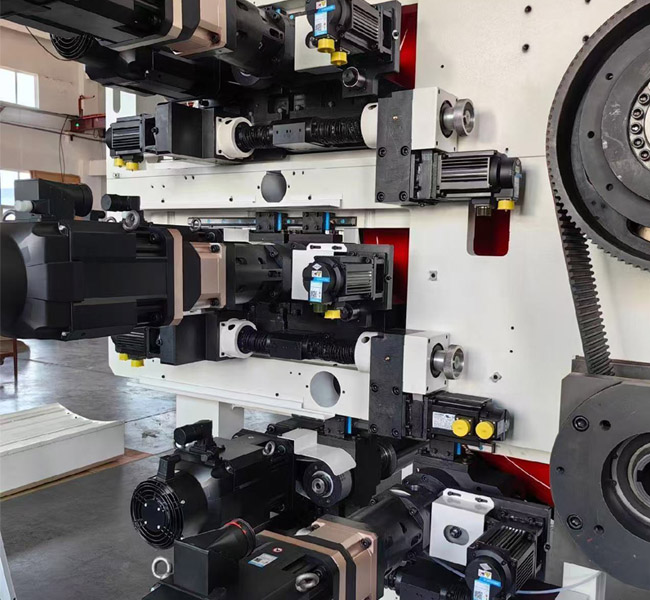

All the electric component adopts famous brand in order to have more stable performance and better life time.we can customized different machine according to your requirement.

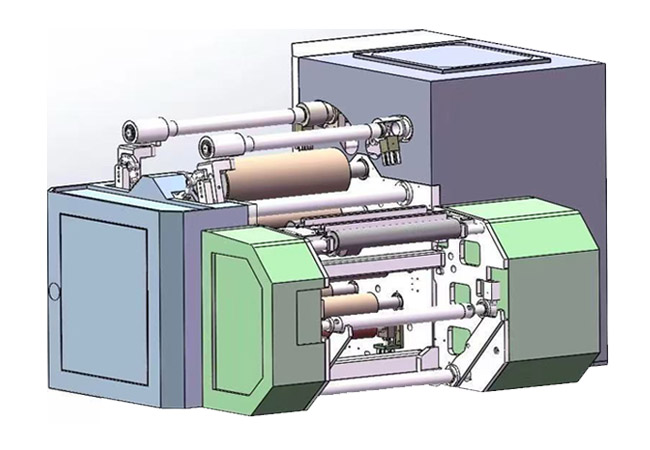

ZONBON offer horizontal,Vertical,surface,Gantry large roll with different speed slitting machine.

ZONBON have been more than 18years experience in slitting machine field.Our slitting machine adopt latest technology,it can slit large roll with small roll with narrow width for different slitting material,such as paper,film.

All the electric component adopts famous brand in order to have more stable performance and better life time.we can customized different machine according to your requirement.

- The slitting machineas a core equipment in modern industrial precision processing, It impacts production efficiency and product quality directly through its performance and reliability. ZONBON adopts a professional perspective to systematically analyze the key aspects of the slitting machine's lifecycle management—from selection and design to after-sales service—helping enterprises optimize production efficiency.

- Selection: Precise Demand Matching :

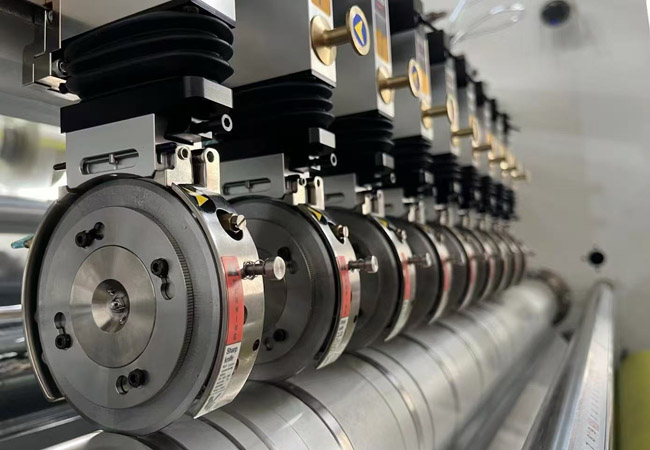

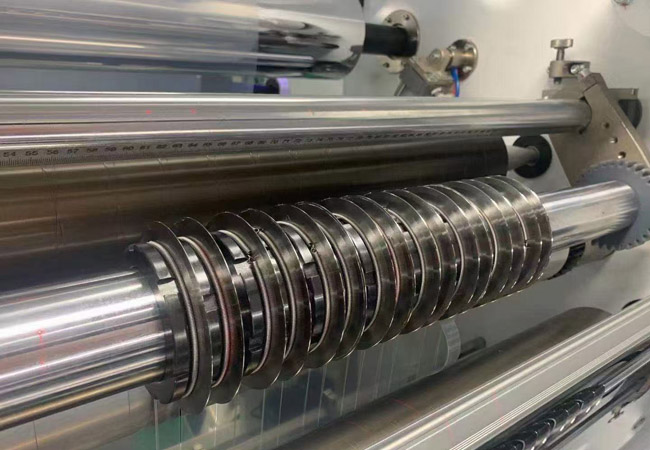

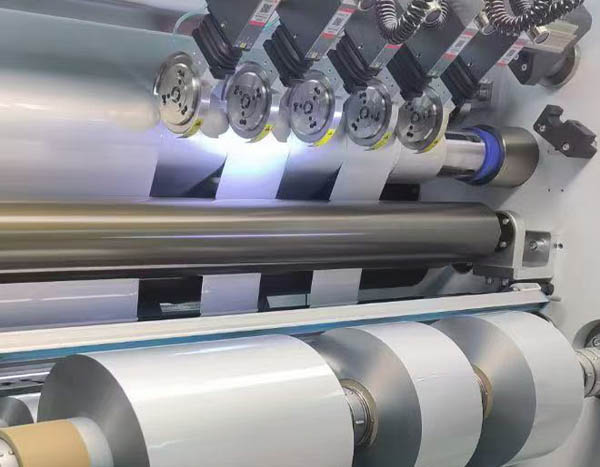

Material Compatibility: Choose slitting methods (rotary blade, air knife) based on substrate characteristics (film, paper, metalize foil).

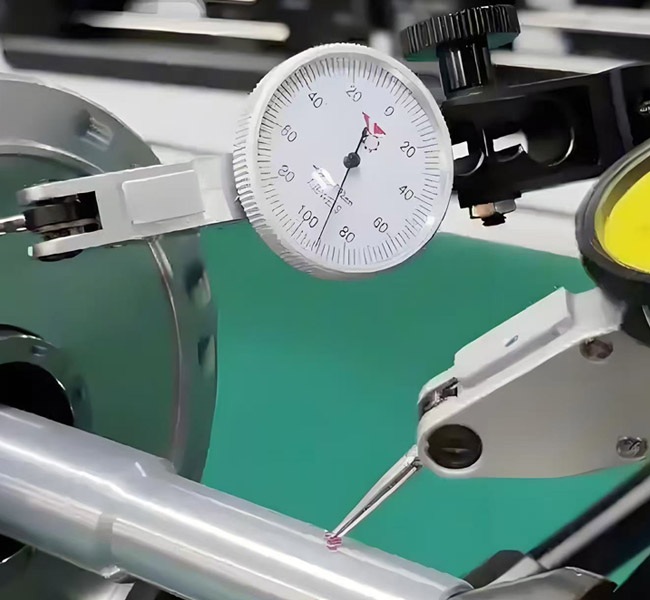

Technical Parameters: Focus on slitting precision (±0.1mm), speed (≤800m/min), and automation level (PLC control).

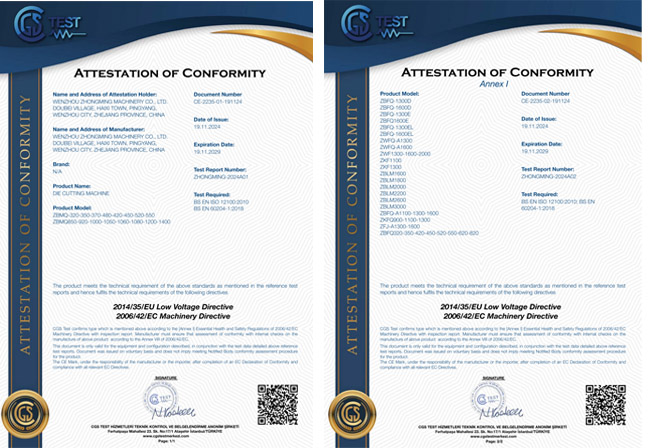

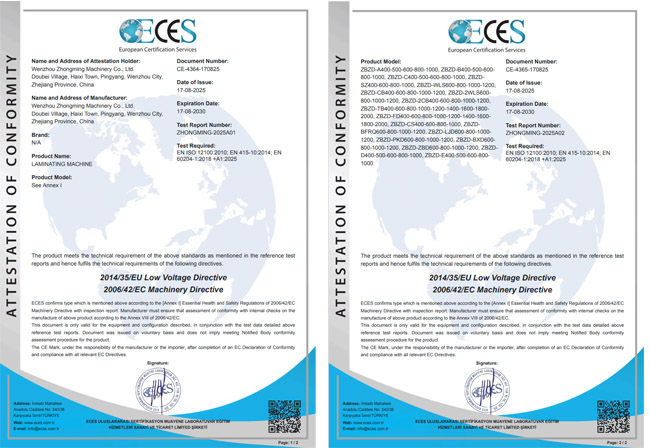

Brand Evaluation: Prioritize suppliers with ISO certification and industry case studies to ensure technical maturity.

● Slitting Width:2-11000mm

● Slitting Speed:100-1000m/min

● Rewinding Diameter:100-2000mm

● Unwinding Diameter:600-2500mm

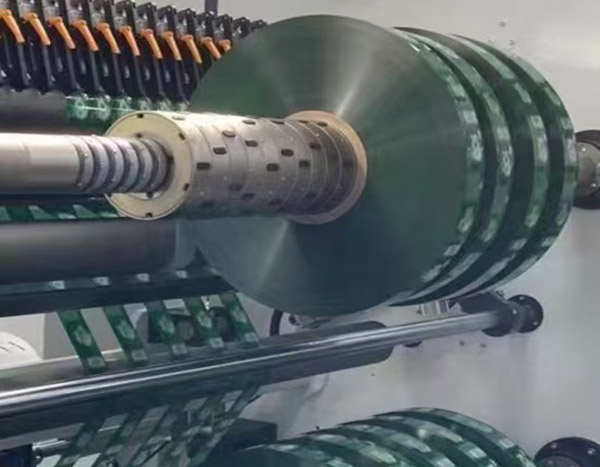

● RewindingShaft size:Shaft 0.5',1',3',6'

● Unwinding Shaftless:3',6',12'

● Unwinding Method:Shaft,Shaftless,Loading Weight:100-3000KG

● Motor:Siemens,Yaskawa,Delta,China Brand Etc

● Tension Control: PLC,Delta,Siemens,Mitsubishi,China Brand

● Touch Screen: Siemens,Vienview,Delta,China Brand etc

● Web Guide:BST,Pausource,China Brand

● Slitting Method:Razor,Circular Blade,Penumatic Blade

● Rewinding Method: Single Shaft,Double Shaft,Center Rewinding,Surface Rewinding

● Unwinding: inflatableshaft/shaftless

● Rewinding: air shaft/Slipshaft/Multi-station winding

● Extra Option: Automatic Blade Postioning system

● Automatic Unloadinig and Uploading

● Light Loading: manipulator

● Heavy Loading: Power Roll

● Infrared ray positioning: For Blade and Paper Tube

In high-volume production, consistent precision isn’t just desirable—it’s profit-critical. Our slitting machine integrates proprietary dynamic tension control with micron-level laser-guided alignment, actively compensating for material inconsistencies (like thickness variations or humidity-induced stretch) in real-time. Unlike conventional systems relying on static settings, this means every slit—from the first to the thousandth coil—maintains tolerances within ±0.05mm, regardless of runtime. For converters handling premium films, foils, or battery electrodes, this eliminates edge defects like micro-burrs or tensile fractures that trigger downstream rejects. The financial impact is transformative: reducing trim waste by 15–30% directly slashes raw material costs, while near-zero defect rates minimize customer chargebacks. Operators spend less time on manual adjustments and quality triage, redirecting labor toward value-added tasks. For example, a packaging converter running PET film 24/7 could save over $150,000 annually in reclaimed material alone. This isn’t merely "accurate slitting"; it’s predictable precision engineered into every cut, turning quality compliance into a competitive profit center.

Today’s labor constraints demand machinery that works smarter, not harder. Our slitting machine features an AI-driven operational ecosystem that autonomously optimizes speed, tension, and blade wear. Using embedded sensors and historical job data, it dynamically adjusts parameters during runtime—anticipating splice points, adapting to material lot changes, and even recalibrating knife pressure as blades dull. This self-correcting intelligence reduces setup/changeover time by up to 70%, transforming 45-minute manual calibrations into <10-minute automated routines. Operators transition from constant troubleshooting to oversight, managing multiple lines via a unified dashboard that predicts maintenance needs (e.g., "Replace left deck blades in 8 hours") and prescribes optimization tweaks. For a nonwoven producer running 20+ changeovers daily, this autonomy recaptures 100+ production hours monthly—equivalent to adding a full shift without hiring. The machine doesn’t just perform tasks; it learns and evolves, compressing downtime while maximizing asset utilization. This isn’t automation—it’s autonomous production resilience, delivering ROI through relentless operational efficiency.

ZONBON have professional engineer and team that have been more than 20years experience,all the design meet the latest requirement of the current market to help customer solve the problem,win your business.

- Standardized Procedures: Strictly enforce assembly precision tests (e.g., spindle radial runout ≤0.02mm).

Environmental Control: Temperature-controlled workshops ensure machining consistency of core components ( cutting tools).

.

- Factory Testing: 72-hour continuous load operation to validate equipment stability.

- International Standards: Compliance with CE safety certification and GB/T 19001 quality management system requirements.

Your dedicated Zonbon support triad:

1) Rapid Response: Provide on-site technical support within 48 hours, with spare parts inventory coverage reaching 95%.

2) Value-Added Services: Regular maintenance inspections and operator training to extend equipment lifespan.