Your Expert in Laminating Machine

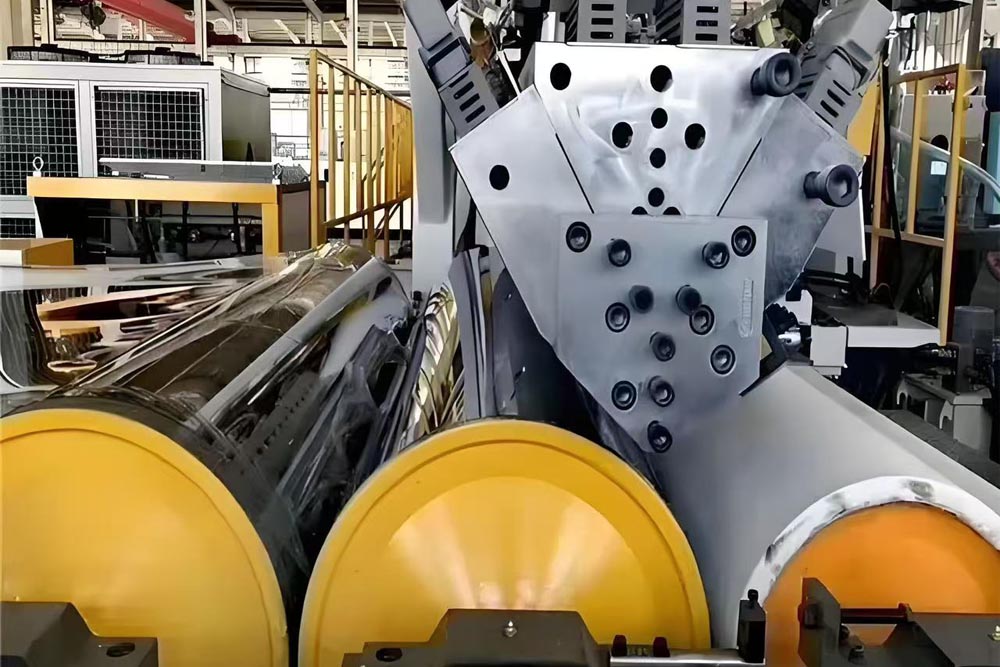

As one of expert of laminating machine manufacturer,we provdie differnt type of laminating machine such as solvent laminating machine, solventless laminating machine , extrusion laminaitng machines.

As one of expert of laminating machine manufacturer,we provdie differnt type of laminating machine such as solvent laminating machine, solventless laminating machine , extrusion laminaitng machines.

ZONBON have different type of laminatining machine include solvent lamianting machine,solventless laminating machine,extrusion laminaitng machines.

ZONBON have different model laminating machine,it can laminating different material.

ZONBON have different type of laminatining machine include solvent lamianting machine,solventless laminating machine,extrusion laminaitng machines.

• Advantages:

- Wide Applicability: Can handle various substrates (e.g., BOPP, PET, aluminum foil, nylon, PE, etc.) with flexible combinations.

- Mature Process: Stable technology and extensive operational experience, making it one of the most mainstream lamination methods currently.

- Excellent Product Performance: High bond strength and good transparency of the finished product.

• Limitations:

- Environmental and Safety Pressure: When using solvent-based adhesives, there are VOC emission issues, requiring expensive exhaust gas recovery and treatment systems.

- High Energy Consumption: The oven drying process consumes significant energy.

- Solvent Residue Risk: Potential migration risk for food and pharmaceutical packaging, requiring strict control.

•Advantages:

- Green and Environmentally Friendly: No VOC emissions, compliant with increasingly stringent environmental regulations, representing the future development trend.

- High Efficiency and Energy Saving: No oven required, significantly reducing energy consumption and enabling faster production line speeds.

- High Safety: No risk of solvent residue, making it particularly suitable for packaging with high hygiene requirements like food and pharmaceuticals.

• Limitations:

- Low Initial Strength: Curing requires a certain time (typically 24-48 hours), preventing immediate subsequent slitting or bag making.

- Extremely High Demands on Substrate Tension Control: Requires strict equipment precision and operator skill.

• Advantages:

- Cost Advantage: Uses inexpensive resin instead of adhesive, resulting in low comprehensive cost.

- Functional Integration: The extruded layer acts simultaneously as both the adhesive and a functional layer (e.g., heat-seal layer, moisture barrier), simplifying the structure.

- No Solvent Issues: No chemical solvents are involved in the process.

• Limitations:

- High Equipment Investment:The production line is large-scale with high initial capital expenditure.

- High Energy Consumption: The extruder heating consumes significant power.

- Limited Material Compatibility: Primarily suitable for substrates that bond well with polyolefins.

•Advantages:

- Instant Bonding: Solidifies upon cooling, enabling fast production pace with no curing time.

- 100% Solid Content: No VOCs, environmentally friendly.

- Relatively Simple Equipment: Lower investment and operational costs.

• Limitations:

- Poor Heat Resistance:Hot melt adhesives have limited high-temperature resistance, making them unsuitable for applications like high-temperature retorting.

- Narrow Applicability: Mostly used in non-food packaging fields such as hygiene materials (diapers, sanitary napkins), furniture lining, and automotive interiors.

Zonbon has been at the forefront of packaging industry innovation. We don’t just design and manufacture professional Dry Laminating Machine – we are our customers’ partners in strategic planning too! Our passion for excellence keeps us creating cutting-edge solutions so your business can stay one step ahead.

Our Lamination Machine enginner not only just test machines – they simulate your production reality, we validate every parameter against your specific substrates and throughput goals.

- Choose independent verification or request live video FAT (Factory Acceptance Testing)

- Receive pre-installed maintenance kits (no. of free replacements tailored to your volume)

- Shock-absorbent packaging with desiccant and anti-rust nanotechnology coatings

Your dedicated Zonbon support triad:

1) 14-day on-site operational coaching

2) 365-day warranty covering labor/parts

3) Lifetime access to our proprietary troubleshooting database

Zonbon, The Most Professional Flexible Printing and Packaging Converting Machines Manufacturer Around You.

© 2011-2025 Zonbon Printing & Packaging Machinery Co., Ltd. All Rights Reserved