Blogs

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

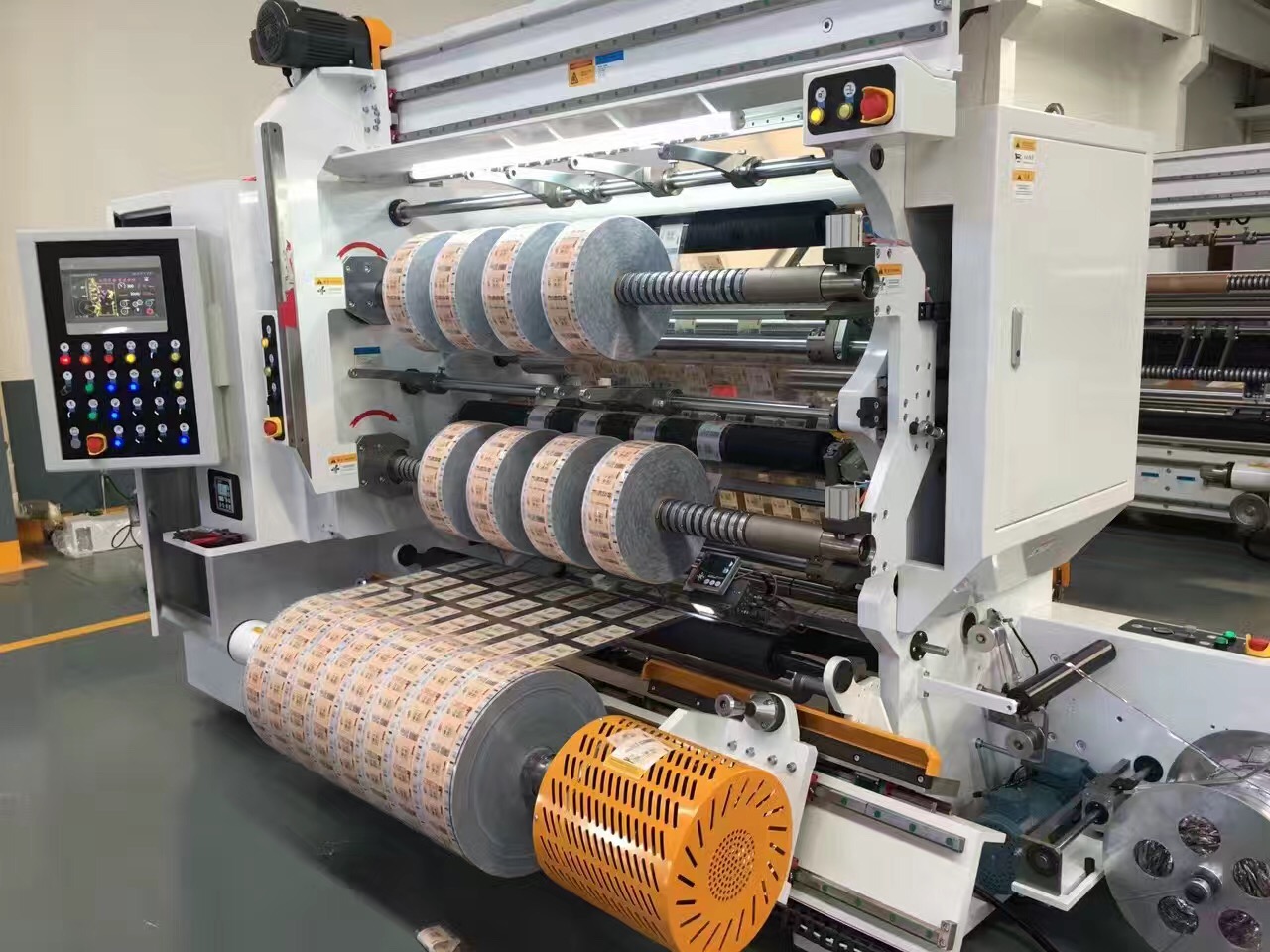

Have you ever wondered about the origin of that numbered ticket you hold while waiting in line at a restaurant? Or pondered the manufacturing process of the paper straw you sip your drink through at a cafe? The creation of such paper products, including that ticket and straw, begins with them being part of a large roll of paper meticulously cut by industrial equipment. This precise cutting is typically accomplished by a slitting machine. So, what exactly is a slitting machine? How does it achieve such fine cutting accuracy? This article will focus on slitting machines, providing a comprehensive analysis of this technology. Whether you are new to the packaging industry, a packaging manufacturer, a slitting machine operator, a newcomer looking to understand the process before purchasing equipment, or an experienced professional seeking to deepen your expertise, this guide will offer practical reference and guidance.

In numerous industrial sectors such as packaging, printing, papermaking, film, metal processing, and composites, the slitting machine plays an indispensable role as a key post-processing equipment. It performs high-speed, high-precision longitudinal cutting of wide web materials, slitting them into several narrower webs of required width to meet the needs of downstream production or final application. With the continuous advancement of industrial automation and intelligence, modern slitting machines have evolved from simple mechanical cutting tools into high-tech equipment integrating precision machinery, automatic control, and sensing detection. This article will systematically elaborate on the definition, working principles, core classifications, key technical parameters, main application areas, and future development trends of slitting machines.

A slitting machine, often referred to in English as a Slitting Machine or Rewinder, is an industrial device that continuously and precisely slits and rewinds large-format roll materials (such as paper, plastic film, metal foil, non-woven fabric, composites, etc.) along their length direction. Its core functions can be summarized as "slitting and rewinding":

Slitting: Using precision blades (circular knives, razor blades, etc.) to longitudinally divide the master roll into multiple strips.

Rewinding: Separately rewinding the slit strips into independent, neat, and tightly wound sub-rolls.

This process not only changes the material's width but also ensures the quality of the rewound rolls (such as uniform winding tension, neat end faces, absence of wrinkles or damage), directly impacting the efficiency and yield of subsequent processing steps.

Standard slitting operations follow a coherent process flow, with the core principles as follows:

Loading and Unwinding: The master roll is loaded onto the unwind shaft. Modern slitters are typically equipped with devices like air shafts and hydraulic loading carts, and integrate automatic edge position control (EPC) systems to ensure constant material position before entering the cutting zone.

Tension Control: This is the soul of the slitting process. The system, through components like magnetic powder clutches, vector frequency conversion motors, and tension sensors, forms open-loop or closed-loop control systems to establish and maintain stable material tension at multiple points such as unwinding, slitting traction, and rewinding. Excessive tension can cause material stretching, deformation, or even breakage; insufficient tension leads to loose rewinding and uneven end faces.

Slitting Execution: The material passes through the slitting knife holder. Depending on material characteristics and process requirements, two main slitting methods are employed:

Circular Knife Slitting: Divided into tangential slitting (where the cutting edges of the upper and lower circular knives move in opposite directions, similar to scissors, suitable for films, thin paper, etc.) and crush cut slitting (where the upper circular knife presses the material against a lower anvil roller, suitable for thicker or harder materials).

Razor Blade Slitting: Utilizes a single-edge razor blade to score and cut the material at high speed, primarily used for extremely thin, soft film materials, resulting in smooth, burr-free cuts.

Edge Trim Removal: Waste edge trims generated from slitting are promptly removed by edge suction fans or winding rollers, maintaining a clean working environment.

Rewinding: The slit strip materials pass through guide rollers and are synchronously rewound by multiple independent rewind shafts. Advanced rewinding mechanisms use AC servo independent drives, combined with pressure roller or contact winding technology, to ensure uniform winding density for each sub-roll.

Unloading and Labeling: After rewinding is complete, the equipment can automatically or semi-automatically unload the sub-rolls and may integrate functions like labeling, weighing, and packaging.

Based on equipment structure, process orientation, and automation level, slitting machines can be classified into the following categories:

Horizontal Slitting Machine: The main shaft is arranged horizontally. It offers stable structure and convenient maintenance, making it the most widely used type.

Vertical Slitting Machine: The main shaft is arranged vertically. It has a small footprint and is often used in space-constrained environments or for handling special materials.

Dual-Station Slitting Machine: Equipped with two unwind or rewind stations, enabling non-stop roll changeover, greatly improving production efficiency.

Paper Slitting Machine: Specifically designed for the paper industry to slit large paper rolls into smaller rolls for printing and packaging.

Film Slitting Machine: Designed for plastic films like BOPP, CPP, PET, PE, and aluminum-plastic composite films, emphasizing dust-free, scratch-free operation and high-precision tension control.

Metal Foil Slitting Machine: Used for slitting copper foil, aluminum foil, etc., requiring high-hardness, high-wear-resistance blades, and featuring anti-static and dust removal functions.

Non-woven/Composite Material Slitting Machine: Handles elastic or irregularly structured materials, requiring special tension adaptation and edge guiding systems.

Semi-Automatic Slitting Machine: Some processes (like loading, unloading, splicing) require manual assistance.

Fully Automatic Slitting Machine: Integrates automatic loading, automatic threading, automatic tension control, automatic unloading, automatic labeling, etc., controlled centrally by PLC (Programmable Logic Controller) or industrial computers. It is a core unit of smart factories.

To evaluate the performance of a slitting machine, focus on the following core parameters:

Maximum Unwind/Rewind Diameter: Determines the amount of material processed per batch. Common ranges are from Φ600mm to over Φ2500mm.

Maximum Slitting Width: The original web width the machine can handle, e.g., 1300mm, 3000mm.

Slitting Speed: Maximum mechanical line speed, a direct reflection of production efficiency, ranging from tens to over a thousand meters per minute.

Slitting Accuracy: Width tolerance of sub-rolls, typically required to be within ±0.1mm or even ±0.05mm. It is a comprehensive reflection of the machine's mechanical precision, blade precision, and control system level.

Minimum Slitting Width: The narrowest strip width the machine can slit stably, limited by knife holder structure and control system.

Tension Control Range and Stability: Usually expressed as a percentage control accuracy, it is key to ensuring rewinding quality.

Control System: PLC brand, HMI (Human-Machine Interface) functionality, support for bus communication (e.g., Profibus, Ethernet/IP), and capabilities for data acquisition and remote diagnostics.

The application of slitting machines permeates almost all industries requiring web material processing:

Packaging and Printing Industry: Slitting pre-printed roll labels, flexible packaging materials, cardboard, etc.

Plastic Film Industry: Post-processing slitting of cast films, blown films, biaxially oriented films.

Lithium Battery Manufacturing: Precision slitting of electrodes (coated foil for anodes and cathodes), with extremely high requirements for dust-free, burr-free operation and tension control.

Papermaking Industry: Slitting and rewinding of cultural paper, specialty paper, tissue parent rolls.

Non-woven Fabric Industry: Slitting of non-woven fabrics, meltblown fabrics.

Metal Processing: Precision slitting of copper, aluminum foils, and strips.

Electronic Materials: Slitting of tapes, protective films, optical films (e.g., polarizers, brightness enhancement films).

Currently, slitting machine technology is rapidly developing in the following directions:

Intelligence and Digitization: Integration with MES (Manufacturing Execution Systems) to achieve order management, automatic calling of process parameters, production data traceability, quality analysis, and predictive maintenance.

High-Speed and High-Precision: Adoption of advanced drive and control technologies like linear motors and magnetic levitation bearings to ensure slitting accuracy and stability while increasing speed.

Modularity and Flexibility: More elastic equipment design, capable of adapting to orders with different materials and process requirements through quick module changes, meeting the trend of small-batch, multi-variety production.

Energy Saving and Environmental Protection: Application of energy feedback technology to reduce consumption, optimized design to reduce noise, and better handling of dust and waste generated during processing.

Online Inspection Integration: Direct integration of vision inspection systems, thickness gauges, and defect detection systems into the slitting line, enabling simultaneous production and quality inspection, improving overall quality control.

Robotic Assistance: Robots for automatic loading of raw material rolls; robots for automatic unloading of finished rolls; robotic systems for automatic precise knife setting and arrangement.

As a precision processing bridge connecting upstream production and downstream applications, the technological level of slitting machines directly reflects the manufacturing capabilities of related industries. The development journey of slitting machines, from simple mechanical slitting to highly intelligent processing centers, epitomizes modern industry's continuous pursuit of efficiency, precision, and automation. With the continuous emergence of new materials and processes, and increasingly stringent requirements for product quality, future slitting machines will continue to deepen development in core component innovation, control system upgrades, and full-process integration, providing a solid and reliable equipment foundation for the transformation and upgrading of manufacturing. For users, a deep understanding of the principles, types, and key parameters of slitting machines is the prerequisite for proper equipment selection, process optimization, unlocking equipment potential, and enhancing product quality and market competitiveness.

Material Type: Identify whether the material to be slit belongs to paper (cultural paper, specialty paper), plastic film (BOPP, CPP, PET), metal foil (aluminum foil, copper foil), composite materials (lithium battery separator, adhesive tape), or textiles.

Material Thickness and Tension Sensitivity: Materials of different thicknesses and types have significantly varying requirements for tension control precision. Film materials typically require higher-precision tension control systems.

Material Surface Characteristics: Consider whether the material has coatings, is prone to generating static electricity, its surface friction coefficient, etc. These factors directly influence the selection of guide roller materials and the configuration of static elimination devices on the slitter.

Slitting Width Accuracy Requirements: Determine the tolerance range for slit width based on final product specifications. Generally, precision slitting requires tolerances within ±0.1mm.

Slitting Speed Requirements: Determine the required linear slitting speed (typically ranging from 50 to 1500 meters per minute) based on production capacity requirements.

Rewind Diameter and Method: Specify the maximum rewind diameter (common sizes are 600mm, 800mm, 1000mm, 1500mm) and the rewinding method (center winding, surface winding, or center-surface combined winding).

Slitting Method Selection: Choose between razor cut or shear cut based on material characteristics. Hard materials often use shear cut, while soft films often use razor cut.

Tension control is the core performance indicator of a slitter, directly determining slitting quality and rewind neatness:

Fully Automatic Tension Control System: Utilizes a closed-loop control scheme with PLC + servo motor + tension sensor to achieve constant tension control throughout the entire process of unwinding, traction, and rewinding.

Segmented Tension Control Capability: High-quality equipment should feature tension taper control, automatically adjusting the tension curve as the roll diameter changes.

Tension Fluctuation Range: High-end slitters can control tension fluctuation within ±1%, meeting the needs of precision material slitting.

Drive Configuration: Modern slitters commonly use servo motors to independently drive each unit. Compared to traditional mechanical transmission, this offers advantages of high precision, fast response, and easier maintenance.

Transmission Precision: Pay attention to the configuration of backlash elimination mechanisms and high-precision gear reducers to ensure no speed fluctuation during slitting.

Energy Efficiency: Evaluate the equipment's energy consumption indicators. Slitters equipped with energy recovery systems can reduce energy consumption by over 30%.

Automatic Edge Position Control (EPC): Uses ultrasonic or photoelectric sensors to detect material edge position and real-time adjustment via servo drive.

Guiding Accuracy: High-end systems can achieve guiding accuracy of ±0.1mm, ensuring the material remains in the correct position throughout slitting.

Guide Roller Configuration: Reasonable guide roller layout and surface treatment (chrome plating, ceramic coating) can reduce material scratching and static generation.

Knife Holder Structure: Examine the rigidity, vibration suppression capability, and adjustment convenience of the knife holder.

Tool Material and Design: Select carbide, ceramic, or high-speed steel tools based on material characteristics. Tool angle design must match material properties.

Knife Shaft Precision: The radial runout of the knife shaft should be less than 0.01mm to ensure cutting stability.

Semi-Automatic Slitter: Suitable for small-batch, multi-variety production. Lower investment cost but requires higher operator skill.

Fully Automatic Slitter: Equipped with functions like automatic knife change, automatic splicing, automatic roll unloading. Suitable for large-volume continuous production, significantly reducing labor costs.

Intelligent Slitting Production Line: Integrates intelligent modules like MES systems, vision inspection, quality traceability, enabling digital production management.

Horizontal Slitter: Compact structure, small footprint, suitable for slitting small to medium web widths.

Vertical Slitter: More rational material path, convenient operation, suitable for slitting large-width, heavy materials.

Dual-Position Slitter: Equipped with two rewinding positions, enabling roll change without stopping, improving equipment utilization.

Static Elimination System: Essential for materials like films and papers prone to static electricity; must be configured with ionizing air bars or static eliminators.

Dust Removal and Cleaning Devices: For cleanrooms or applications with high cleanliness requirements, dust removal rollers and vacuum suction systems are needed.

Online Inspection System: Integrates modules like thickness measurement and defect detection for real-time quality monitoring during slitting.

Data Acquisition and Networking: Supports industrial communication protocols like OPC UA, Modbus for easy integration into factory information systems.

Industry Experience and Case Studies: Examine the supplier's successful cases and experience in the target material slitting field.

R&D and Innovation Capability: Evaluate the strength of their technical team, patent portfolio, and new product development capability.

After-Sales Service Network: A comprehensive after-sales service system, sufficient spare parts inventory, and rapid response capability are crucial.

Factory Acceptance Test (FAT): Conduct comprehensive performance testing before equipment shipment to verify all technical indicators.

Material Trial Slitting Verification: Use actual production materials for trial slitting to evaluate slitting quality, efficiency, and loss rate.

Long-Term Operational Stability Assessment: Refer to feedback from existing users to understand long-term operational failure rates and maintenance costs.

Initial Investment Cost: Equipment purchase price, installation and commissioning fees, training costs.

Operational Costs: Energy consumption, tool consumption, maintenance, labor costs.

Return on Investment (ROI): Comprehensively consider the overall benefits from improved production efficiency, reduced material waste, and quality enhancements.

Predictive Maintenance: Based on IoT sensors and big data analysis, enabling equipment failure prediction and maintenance plan optimization.

Adaptive Control: Through machine learning algorithms, enabling slitters to automatically optimize process parameters and adapt to changes in material characteristics.

Digital Twin Technology: Establishing virtual equipment models for process simulation and optimization, reducing trial-and-error costs.

Energy-Saving Technologies: Adopting high-efficiency motors, energy recovery systems, intelligent standby modes, and other energy-saving technologies.

Low-Noise Design: Reducing equipment operating noise through structural optimization and application of soundproofing materials.

Expanded Material Compatibility: Adapting to the slitting requirements of new environmentally friendly materials like biodegradable materials and bio-based materials.

Quick Changeover System: Through modular design, enabling rapid switching between different product specifications.

Expandable Architecture: Supporting the addition and upgrade of functional modules later, extending the equipment's technological lifecycle.

A slitting machine is an industrial device used to precisely cut wide rolls of material into multiple narrow strips longitudinally. The machine employs a high-precision circular blade system to perform continuous slitting of materials such as films, paper, metal foils, and composite materials through processes like unwinding, tension control, slitting, and rewinding.

Core Working Principle: The material is unwound from the unwinding shaft, guided through rollers into the slitting zone, where precision circular blades on the upper and lower shafts perform shear or crush cutting based on preset spacing, longitudinally dividing the material. The slit strips are then wound onto independently controlled rewinding shafts.

Applicable Materials: Films, paper, foils, and composite packaging materials with thicknesses of 0.01mm–0.5mm

Slitting Width Range: 30mm–2000mm (parent roll width)

Number of Slits: 2–50 (depending on material properties and width)

Maximum Speed: 300 m/min

Slitting Accuracy: ±0.1mm (static), ±0.2mm (dynamic)

Blade Shaft System: Hydraulic or pneumatic blade pressure, servo motor-driven

Tension Control: Fully automatic three-stage tension control (unwinding, intermediate, rewinding)

Control System: PLC + touchscreen with parameter storage and recall

Dual-position hydraulic lifting unwinding stand

Magnetic particle brake tension control system

Automatic edge position correction (EPC)

Upper blade shaft (φ120mm, hardness HRC 58–62)

Lower blade shaft (φ150mm, hard chrome-plated)

Blade gap adjustment mechanism (accuracy: 0.01mm)

Waste edge removal system

Independently driven rewinding shafts (6 positions)

Pneumatic pressure roller device

Closed-loop tension control system

Automatic cutting and roll-changing function

Main Controller: Siemens S7-1500 series PLC

HMI: 10.4-inch color touchscreen

Drive System: Servo motors + precision reducers

Detection Devices: Ultrasonic tension sensors, photoelectric edge sensors

Safety System: Emergency stop buttons, safety light curtains, overload protection

Confirm all safety guards are intact

Test emergency stop button functionality

Clear obstacles around the machine

Install blades based on slit width (using specialized spacers)

Adjust blade overlap (recommended: 1/3 of material thickness)

Set blade side clearance (typically 0.003–0.01mm)

Load the parent roll onto the unwinding stand

Verify threading path (refer to machine diagram)

Set initial tension parameters

Input material parameters (type, thickness, width) via HMI

Configure slitting specifications (number of slits, width, tolerance)

Set tension curve (decreasing unwinding tension, increasing rewinding tension)

Configure rewinding parameters (roll diameter, length, roll-changing method)

Start at low speed (≤10 m/min)

Observe slit quality and fine-tune blade positions

Gradually increase to production speed

Monitor tension fluctuations (keep within ±5% of set value)

When the roll reaches the set length, the machine automatically decelerates

New roll shaft pre-starts and synchronizes

Automatic cutting and roll switching

Finished rolls are automatically unloaded while production continues

Edge Quality: Check for burrs or jagged edges

Width Accuracy: Sample measurements every 30 minutes using digital calipers

Roll Quality: Ensure even winding without star or chrysanthemum patterns

Tension Stability: Monitor tension curve and adjust for anomalies

Clean blade shafts and guide rollers (using alcohol and soft cloth)

Check pneumatic system pressure (maintain 0.6–0.8 MPa)

Lubricate rails and bearings (lithium-based grease)

Record operating parameters and anomalies

Inspect blade wear (replace if edge rounding ≥0.05mm)

Clean tension sensor surfaces

Calibrate edge alignment system zero point

Check drive belt tension

Clean servo motor cooling fans

Back up system parameters and process recipes

Replace all bearing seals

Inspect rail straightness and parallelism

Perform full machine calibration (by manufacturer technicians)

Maintain blade usage records (track cutting length, material type)

Hard alloy blade lifespan: ~800–1000 km for films

Blade sharpening standard: Maintain 25°–30° edge angle

Storage: Store in dedicated blade cases with rust prevention

Issue | Possible Cause | Solution

Burred edges | Dull blades, excessive gap | Replace blades, adjust gap

Width variation | Unstable tension, blade shaft runout | Check tension sensors, calibrate shafts

Uneven rewinding | Uneven roller pressure, eccentric parent roll | Adjust roller pressure, reload roll

Alignment failure | Dirty sensor, stuck actuator | Clean sensor, inspect cylinder

System alarm | Overload, temperature anomaly | Check load, cooling system

PLC error codes (see Appendix A)

Servo drive alarm reset procedure

Sensor signal testing (measure 4–20 mA output with multimeter)

Operators must complete 72-hour specialized training

Wear fitted workwear, safety goggles, and cut-resistant gloves

Secure long hair and remove jewelry

Never open guards during operation

Blade adjustments require full shutdown

Engage emergency stop before handling broken material

Depressurize hydraulic systems before maintenance

Power outage: Shut off main power, manually release tension

Material breakage: Hit emergency stop, clear debris before restarting

Fire: Use CO₂ extinguishers (no water)

Taper tension control: Set decay curves based on material elasticity

Dynamic blade spacing: Compensate for elastic material width changes

Adaptive roll diameter: Optimize tension algorithms for diameter variations

Connect to MES via Ethernet

OPC UA support for real-time data upload

Traceability: Link each roll to its process parameters

Appendices

A. PLC Error Code Reference

B. Recommended Spare Parts List

C. Process Parameters for Different Materials

D. Manufacturer Contact (ZONBON Machinery; WhatsApp +86 159 5876 6608)

pre: -

next: -