Blogs

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

Pressing Stroke of the Blade Holder: The pressing pressure of the blade holder is not only related to the force from the transmission shaft but also significantly related to the downward stroke of the blade holder (the pressing stroke also affects the heat seal time).

Transverse blades, usually connected by a pair of left-right lifting rods, have relatively simple stroke adjustment. It only requires adjusting the stroke position of the lifting rods at both ends. Generally, when the bag-making machine presses down and lifts, there should be a 1-2mm stroke distance at the buffer washer position on the screw. Ensure the lifting and pressing distances are consistent at both ends of the blade.

Longitudinal sealing stroke adjustment involves two aspects: the stroke of the entire blade holder lift and the individual stroke adjustment for each blade set on the holder. The blade holder relies on four arms connected to the transmission rocker arm for overall lifting. These four lifting arms move with the rocker arm, responsible for raising and lowering the blade holder. A strong spring is usually sleeved over each lifting arm to maintain the downward stroke of the entire holder and provide elasticity. Each blade set on the holder is locked with individual screws for adjusting the pressure of that specific set, such as inconsistencies in pressure stroke between the head and tail of the blade. This is adjusted via lock nuts to maintain the pressure adjustment of the entire blade combination. The screws adjusting the blade stroke are usually locked with double nuts to prevent loosening due to vibration during the continuous sealing process, which could cause stroke changes and consequently variations in blade pressure.

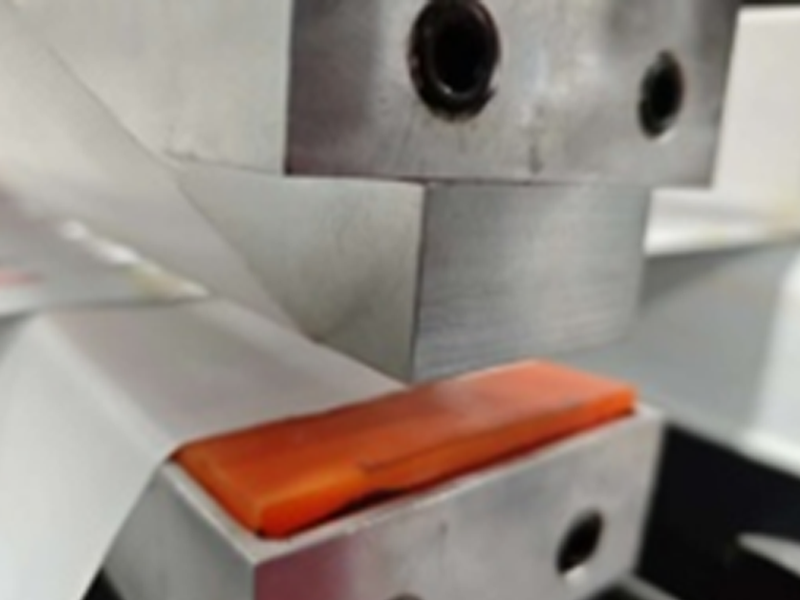

A longitudinal sealing gang typically consists of 3-5 sets of hot blades and corresponding cold knives. To ensure consistent blade pressure, each blade unit is usually equipped with a spring-loaded screw, with the stroke locked by double nuts on the blade holder. Cold knives usually have screws directly connected to the blade.

A. When adjusting the lock nuts of the longitudinal blade stroke screws, extreme caution is needed. Since the screws used are hardened steel and the bottom blade base is aluminum, the aluminum base becomes very soft under high temperatures. The nut must be loosened to adjust the stroke distance. Otherwise, rotating the entire screw can easily strip the threads in the blade base, making it impossible for the screw to securely hold the blade base, leading to equipment quality faults.

B. When adjusting pressure for multiple sets of longitudinal blades, adjusting the stroke of one set will cause pressure changes due to the stroke adjustment, affecting the pressure of adjacent blades.

C. For integrated holders combining hot and cold blades, although the holder lifts as a whole, pressure changes in a single blade set affect the entire gang. The more blade sets there are, the greater the variation, which is clearly disadvantageous for pressure and tension adjustment.

D. An excessively long downward stroke of the blade means the sealing time changes. An overly large pressure stroke might increase the bag's pressing time and could also affect material feeding during bag-making (the blade might not fully disengage when pulling the material), leading to loss of synchronization in material feeding.

E. An excessively short pressing time, or too short a pressing stroke, might result in insufficient heat seal time, preventing heat and pressure from penetrating the film adequately, causing weak seals.

F. When adjusting blade pressure, it is best to do so without heating first. Loosen the gang nuts, perform the pressing adjustment, ensure consistent pressure, then heat up and start the machine. Unused blade sets can be moved away or locked suspended with nuts to avoid affecting pressure during sealing.

Sealing Blade Area: Due to different widths of heat-sealed edges on bags, the chosen blade width also varies. Blade widths from 5mm to 80mm are common. When the blade width is too wide, the contact area for the downward pressure increases significantly, reducing the actual pressure applied to the film. This is an important factor affecting heat seal pressure.

From the pressure formula P (Pressure) = F (Vertical Force) / S (Area), it is known that a wider blade means a larger area, resulting in smaller pressure applied to the heat seal layer. Therefore, experienced machine operators often increase the pressing depth of the blade gang when using wide blades to increase pressure and achieve better heat seal effect.

In practical application, because wide blades have a larger area, not only is the pressure applied to the heat-seal film relatively smaller, but the heat consumption is also greater. In colder weather, attention must be paid to ensuring the temperature loss of wide blades meets the actual needs of bag production. If heating power is insufficient, higher-power heating rods can be replaced to avoid simultaneous insufficiency of both temperature and pressure, leading to weak seals.

pre: -

next: -

Zonbon, The Most Professional Flexible Printing and Packaging Converting Machines Manufacturer Around You.

© 2011-2025 Zonbon Printing & Packaging Machinery Co., Ltd. All Rights Reserved