Blogs

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

In actual bag-making processes, many heat sealing problems occur, such as weak seals, bubbling at the seal edges, regressing side seals, poor air tightness, and brittle seal lines. Apart from temperature factors, the cause of these issues is most likely due to changes in heat seal pressure.

During the bag-making process, many factors can cause pressure changes. Besides possible changes in the mechanical pressure of the bag-making machine itself, other variables such as deformation of the sealing blade, misalignment of the silicone pad, deformation of the silicone pad, adhesive sticking to the sealing blade, damage to the high-temperature cloth, and variations in material thickness can all potentially cause pressure changes.

Often, due to operational oversights, or operators not fully understanding the principle of heat sealing, the impact of pressure changes is easily overlooked, leading to a series of heat seal quality issues that seriously compromise the heat seal quality of the bags.

The main reasons for pressure changes can generally be categorized into the following six dimensions: the mechanical pressure of the sealing blade, changes in the sealing blade, changes in the silicone pad, changes in the high-temperature cloth, the heat-seal material, and pressure changes induced by temperature.

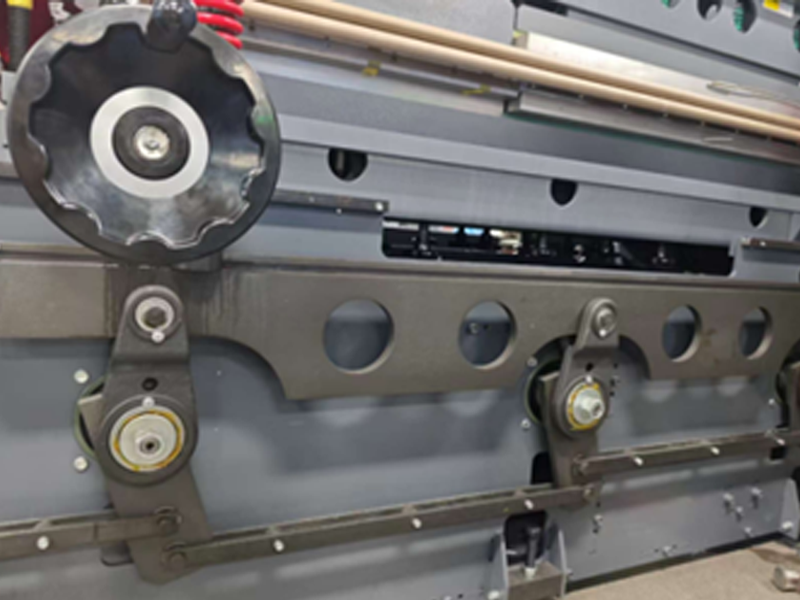

(I) Mechanical Pressure of the Sealing Blade: Since the sealing blade is installed on the blade base, which is in turn connected to the blade holder, the pressure is provided by a transmission mechanism driving a rocker arm to perform the lifting action (the pressing action). This pressure is transferred to the blade holder (longitudinal blades are on a gang mount), which then drives the sealing blade base to press. Therefore, the sources of pressure are:

Pressure transmitted to the blade holder via the rocker arm: The lifting force for the blade holder is provided by the mechanical rocker arm. Through the transmission of a crank arm, the rocker arm provides the pressing action to the blade holder according to the machine's speed rhythm.

The mechanical power source of the bag-making machine itself determines the lifting force. This is related to the machine's inherent design capability. Generally, heavy-duty bag-making machines require reinforcement of the entire transmission mechanism to ensure sufficient pressure.

The buffer spring on the lifting rod serves to cushion both the rebound and the downward pressure.

The rocker arm and its connection points on the bag-making machine act as the mechanical lifting points providing vertical lift for the blade gang. Typically, needle roller bearings provide the lifting support for the blade holder arm. The capacity of these needle roller bearings is mechanical, acting as the fulcrum where horizontal lateral force from the rocker arm is converted into vertical force. This point is highly prone to bearing damage due to uneven force, affecting the power source for the blade gang pressure.

The lifting of the sealing blade holder arm is connected to the transmission rocker arm via a lead screw and a movable slider. The blade holder (especially the longitudinal blade holder) is usually supported by four lifting arms simultaneously. Due to gaps between the slider and the transmission rocker arm, or inconsistent pressure borne by the four lifting arms (e.g., uneven adjustment of the blade gang pressure), localised pressure or uneven force distribution can occur. In severe cases, this can lead to breakage at the bottom lead screw of the lifting arm (since the connection between the lifting arm and the rocker arm is often threaded to connect to the slider, the local strength of the threaded part is naturally less than that of the arm itself), affecting the pressure of the sealing blade.

The lifting arms of the sealing blade holder are usually fixed with bronze bushings to maintain the precision of their up-down swing. Prolonged wear can lead to bushing wear, resulting in insufficient mechanical precision, affecting the uniformity of force on each arm during lifting, and consequently affecting the bag-making pressure.

The base of the sealing blade is typically heated by cartridge heaters inside an aluminum base. The aluminum base, serving as the foundation and support for the sealing blade, has its machining and installation precision significantly impacting pressure. Longitudinal blades are usually fixed with 2-3 set screws locking the base blade seat onto the blade holder bracket. To adjust and balance pressure, an additional 4-5 spring-loaded screws are typically used to connect the base blade to the bracket plate of the blade holder, serving as pressure balance adjustment for the sealing blade. Pressure can be adjusted via the springs. The lower end of the screw is threaded into the sealing blade base, and the upper end usually uses double nuts to lock the sealing blade. The locking position of the nuts maintains the pressure adjustment relationship between a single blade and the entire blade gang.

Mutual influence of pressure between multiple blades on the longitudinal blade holder. Longitudinal sealing usually involves multiple sets of blades on the same holder pressing down simultaneously, causing pressure interference between blades. Especially nowadays, many bag-making machine manufacturers place the longitudinal cold knife and the longitudinal hot sealing blade on the same gang mount, which is not conducive to observing the sealing position. Furthermore, having too many or overly long blades on a single gang mount increases the pressure variations between them, making it more complex.

Theoretically, to ensure consistency of heat sealing, all sealing blades need to be at the same height and under equal pressure (lifting and pressing simultaneously), meaning they press down, make contact, and lift off levelly and simultaneously. This ensures consistency in pressing and force application. However, in actual production, factors like equipment machining precision, machine installation levelness, operator adjustment skill, machine control performance, and variations in film and equipment, especially under the pressure of complex multi-gang mounts, make pressure adjustment very complicated. Achieving uniform consistency is extremely difficult.

If one particular blade or point contacts first, it can cause a delay in the downward pressure of surrounding blades, leading to inconsistent pressure across the entire heat sealing gang. When the pressure deviation is severe, obvious pressure marks can be seen on the heat-sealed surface, often due to localised pressure unevenness.

The mechanical performance of the sealing blade pressure needs consideration during the mechanical structure design phase to ensure rationality. Simultaneously, maintaining machining and assembly precision is crucial to ensure the blade holder is installed at the same pressing level, maintaining pressure consistency when the blades press. This typically needs to be verified and accepted during the equipment acceptance stage.

pre: -

next: -

Zonbon, The Most Professional Flexible Printing and Packaging Converting Machines Manufacturer Around You.

© 2011-2025 Zonbon Printing & Packaging Machinery Co., Ltd. All Rights Reserved