Blogs

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

We share with you the latest industry trends, try to solve all your questions about flexible packaging machines and printing machines as well. Read our blogs to keep abreast of what’s new in the industry and in Zonbon.

In the flexible packaging industry, lamination is a crucial process. In recent years, with the increasing maturity of solvent-free lamination processes, flexible packaging lamination has gradually evolved into a situation where dry lamination and solvent-free lamination complement each other's advantages and coexist. However, the development of dry lamination has been relatively slow, constrained by factors such as production speed, cost, and cycle time. In recent years, flexographic adhesive coating technology has gradually emerged. As a new type of dry lamination adhesive coating process, it effectively solves the problem of surface quality in high-speed lamination, can adapt to high-concentration adhesive application, significantly reduces solvent usage, and has thus become a major focus of attention in the flexible packaging industry.

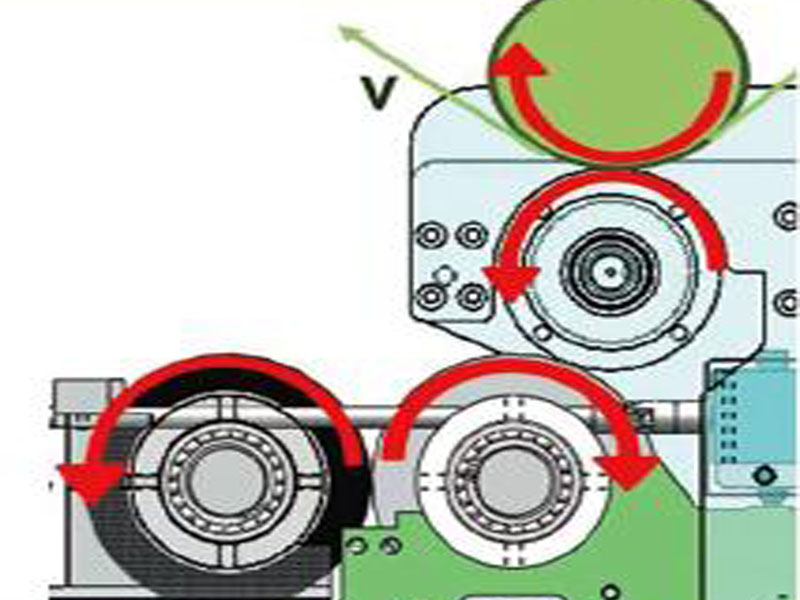

The structure of flexographic adhesive coating is quite unique, somewhat similar to the five-roll transfer coating method used in solvent-free lamination, but with differences. Due to the characteristics of the adhesive, flexographic coating typically adopts a "four-roll transfer" method, with rubber rolls and steel rolls alternating in arrangement. Some equipment manufacturers therefore call it "Semi-Flexographic Coating". The structural principles are largely similar; both control the adhesive application amount through the speed differences and gaps between the rolls. The key lies in the manufacturing precision and control accuracy of the rolls. Based on the depth of understanding of the lamination process, the application level of the equipment can vary.

As shown in the diagram on the right, the two rolls immersed in the adhesive pan are sequentially the feed roll and the metering roll, operating at a specific speed ratio. The rubber roll acts as a "doctor blade", scraping off excess adhesive. The adhesive is transferred from the metering roll to the applicator roll (often designed as a sleeve-type rubber roll for quick job changes), and then from the applicator roll onto the substrate wrapped around the top steel pressure roll, completing the adhesive transfer coating.

In the flexographic coating system, precise control of the adhesive application amount is core. However, unlike traditional gravure roll coating, it is not simply determined by the working solution concentration and the line count of the anilox roll. Instead, it is influenced by four key factors collectively:

Firstly, the gap between the feed roll and the metering roll is adjustable, allowing for changes in the application amount.

Secondly, changes in the working solution concentration directly affect the application amount.

Thirdly, changing the metering roll to one with a different line count can also adjust the application amount, although equipment manufacturers generally do not recommend frequent changes of the anilox roll.

Fourthly, the speed difference between the applicator roll and the metering roll also causes variations in the application amount. Particularly, the gap and speed difference between the metering roll and the applicator roll greatly improve the surface coating state of the adhesive, enabling a more uniform and smooth coating even at very high adhesive concentrations.

(1) Use of Ultra-High Concentration Working Solutions

In traditional direct gravure roll coating, the typical working solution concentration is 30%~35%. Leveraging its unique mechanical structure and control system, flexographic coating technology can achieve a good surface coating state even at ultra-high working concentrations (40%~55%).

Taking a common 75% solid content adhesive as an example: under conventional coating methods, the working concentration is 30%~35%, whereas with flexographic coating, it can reach 40%~50% or higher. This means that using flexographic coating can significantly reduce solvent consumption.

Calculations show that with traditional gravure coating (Base : Hardener : Solvent = 20 : 4 : 30), the concentration is about 33.3%. With flexographic coating (Base : Hardener : Solvent = 20 : 4 : 12), the concentration is 50%. This saves 30 - 12 = 18kg of solvent per batch of adhesive, equivalent to saving 0.75kg of solvent per kg of adhesive. Estimating solvent cost at 7000 RMB per ton, saving 750kg solvent equals 750kg × 7 RMB/kg = 5250 RMB. Thus, using flexographic coating technology can significantly reduce solvent costs.

However, as the working concentration increases, the adhesive viscosity changes more rapidly, which can affect the surface coating state. Therefore, when producing at ultra-high concentrations like 50%, viscosity changes must be strictly controlled. While viscometers can control viscosity changes due to solvent evaporation, it's difficult to fully control viscosity changes resulting from the reaction between adhesive components A and B. With manual adhesive mixing, this viscosity change is almost uncontrollable. Therefore, it is recommended that manufacturers use automatic adhesive mixing machines to prepare adhesive every 15-20 minutes, thus effectively controlling viscosity.

(2) Significant Reduction in Adhesive Application Weight

In traditional gravure roll dry lamination production, a common misconception is to increase the adhesive application weight to improve coating appearance and meet lamination strength requirements, while overlooking how to improve the surface coating state on the substrate. In reality, the smoothness of the adhesive layer and the uniformity of the coated surface are the key factors determining product quality. The application weight should be determined by the surface coating state of the adhesive, not simply "the more, the better." Compared to direct gravure coating, flexographic coating can greatly improve the surface coating state of the adhesive, creating favorable conditions for reducing the application weight.

For example, in some practical production cases, for the same material structure and printed film meeting required lamination performance indicators, the application weight was 4.2~4.5 g/m² using a gravure roll. After switching to flexographic coating for laminating pure aluminum foil, the application weight could be reduced to 3~3.5 g/m². Where the gravure roll application weight was 3~3.5 g/m², flexographic coating could reduce it to around 2.5 g/m², a reduction of 15%~25%. Extensive production data indicates that for some products, the adhesive cost using flexographic dry lamination can reach levels roughly equivalent to solvent-free lamination, while achieving higher lamination quality and production efficiency. However, due to differences in product structures/performance and operator skill levels, reducing the application weight should follow a gradual principle, starting with small batch trials to ensure product quality is not affected.

(3) Improved Production Efficiency

Dry laminators employing flexographic coating are typically high-end machines with excellent overall performance, offering significantly higher production efficiency compared to standard dry laminators. Some machines can operate at speeds up to 300 m/min and are capable of applying adhesive to aluminum foil. For order changes, since there's no need to change anilox rolls to adjust application weight as in traditional gravure coating, simply adjusting relevant parameters suffices. Furthermore, the applicator roll uses a sleeve design, allowing different size sleeve pressure rolls to be changed within 5 minutes. This saves at least 30 minutes per order changeover, greatly enhancing production flexibility and efficiency.

(4) Reduced Comprehensive Costs

Considering the solvent cost savings from using ultra-high concentration working solutions and the adhesive savings from reduced application weight, flexographic coating offers a significant reduction in lamination costs compared to gravure roll coating, generally ranging from 30% to 50%. Taking the 75% solid content adhesive example, calculations show substantial savings in adhesive usage cost with flexographic coating versus gravure coating. Moreover, as flexographic coating technology improves production efficiency and reduces changeover time, it indirectly lowers production costs and reduces energy consumption per unit of capacity.

Currently, leading domestic equipment manufacturers are continuously launching dry laminators equipped with flexographic coating technology, and more flexible packaging companies are beginning to notice and purchase such equipment. With ongoing technological development and refinement, flexographic coating technology is expected to be further optimized in the future. On one hand, adhesive development may focus on creating adhesives more suitable for flexographic coating, better adapting to ultra-high concentration use and lower application weight requirements while further improving product quality. On the other hand, equipment manufacturers will continue to improve equipment performance, stability, and automation levels, while reducing equipment costs, promoting wider application of flexographic coating technology in the flexible packaging industry.

Thanks to its significant advantages in reducing production costs, improving product quality, and enhancing production efficiency, In today's increasingly competitive market, this technology will become an important means for flexible packaging manufacturers to enhance their competitiveness. It will drive the entire flexible packaging industry towards more efficient, environmentally friendly, and high-quality development, injecting new vitality into flexible packaging lamination.

pre: -

next: -

Zonbon, The Most Professional Flexible Printing and Packaging Converting Machines Manufacturer Around You.

© 2011-2025 Zonbon Printing & Packaging Machinery Co., Ltd. All Rights Reserved